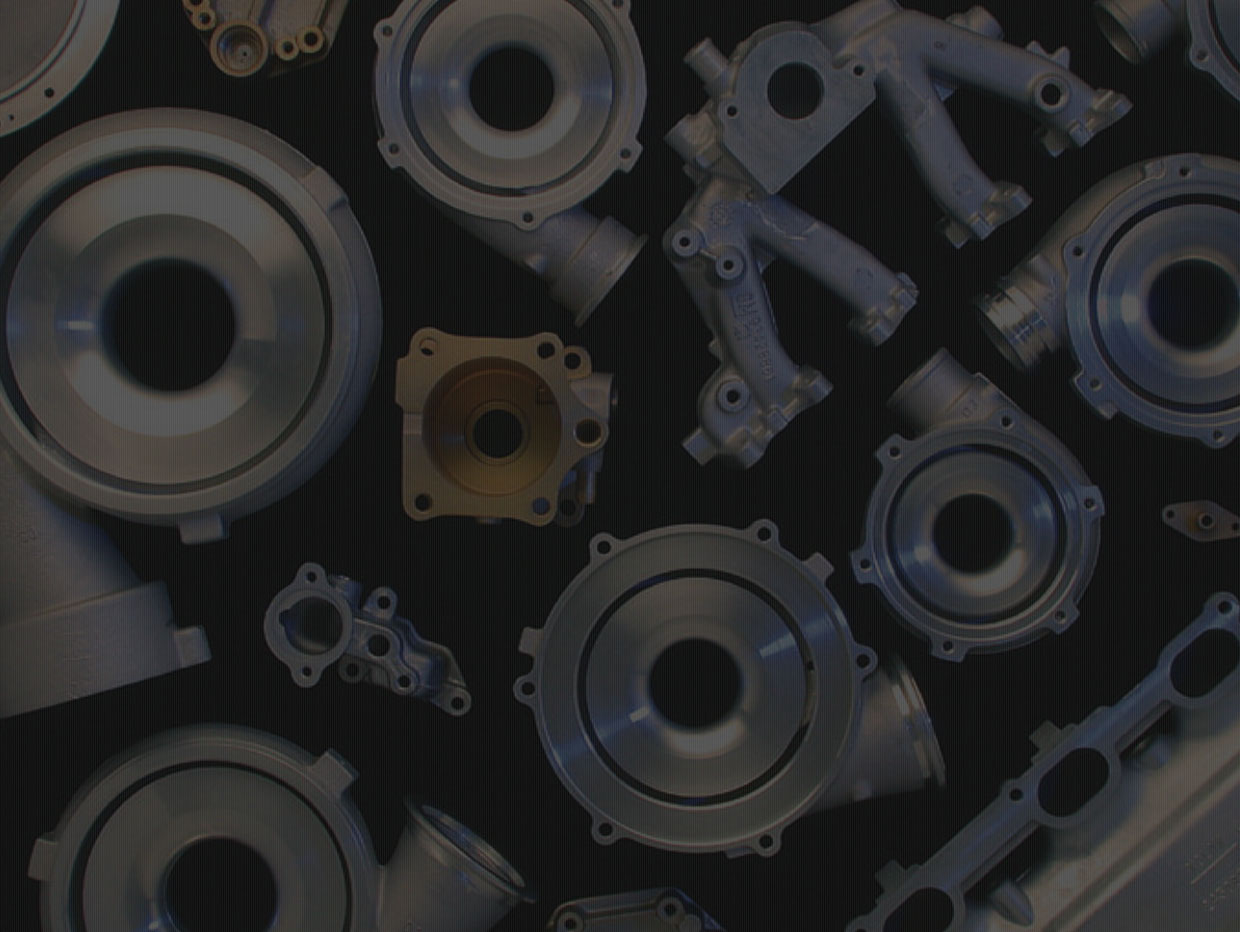

XOLOX | Aluminum, nodular iron, gray iron, steel castings or metal powder parts.

14869

home,page-template-default,page,page-id-14869,qode-quick-links-1.0,vcwb,ajax_fade,page_not_loaded,,qode-title-hidden,qode-theme-ver-11.0,qode-theme-bridge,wpb-js-composer js-comp-ver-5.1.1,vc_responsive

Xolox is a machining house whose main objective is the machining and assembly of aluminum, nodular iron, gray iron, steel castings or metal powder parts. By means of alliances Xolox can provide fully machined castings produced in permanent mold, die cast, sand cast and other processes.

Xolox was founded in 1977 as a private aluminum sand cast supplier for the automotive industry.In 1982 we started the new aluminum permanent mold facilities in Querétaro. In 1989 we started our machining facilities.In December 2000 we sold the aluminum foundry to Le Belier France with whom we continue having a close association.

In January of 2008 we moved to our new facility with 3,300 sq m of manufacturing space on 16,500 sq. m of land

Strengths

- 42 Years’ experience in the automotive industry.

- 36 Years’ exporting 60% of our production.

- 30 Years’ of CNC machining experience.

- We specialize in the machining of castings.

- Medium and high volumes.

- Close tolerance control.

- IATF 16949:2016 and ISO 9001:2015 Certified Quality System.

- Very low employee turnover.

Services

We apply Lean manufacturing techniques as the strategy for continuous improvement. Working groups have been established since 1997 with specific metrics to measure the improvements. As part of our service we regularly perform simultaneous engineering with our customers for new product development, including prototypes. We can use Unigraphics, CATIA or Pro Engineer as mathematical models to generate molds and prototypes.

Product Planning

For new products we use IATF 16949 & APQP guide lines.

These include:

- Feasibility studies

- Simultaneous engineering and prototyping

- Project planning and follow-up

- Control plan, FMEA, flow charts, etc.

- PPAP

- Run at rate or PSO

- Ramp-Up commitments

Historical Products.

- Aluminum Intake Manifolds

- Hydraulic Brake Booster Housing

- Turbo Generator Housing

- Engine Mounting Brackets

- Thermostat Housings

Customers

Quality Certificate

Contact Us

Xolox, S.A. de C.V.

Acceso 2 No. 3 Zona Industrial Benito Juárez,

C.P. 76120, Querétaro, Qro. México.

Sales: +52 1 442 218 66 00 Ext. 115

Fax: +52 1 442 218 66 00 Ext. 107

Quality: +52 1 442 218 66 00 Ext. 109

Administration: +52 1 442 218 66 00 Ext. 113

Email: contact@xolox.com.mx

CALL US NOW